PRODUCT DESCRIPTION

KX2 Inverted

KX2 Inverted

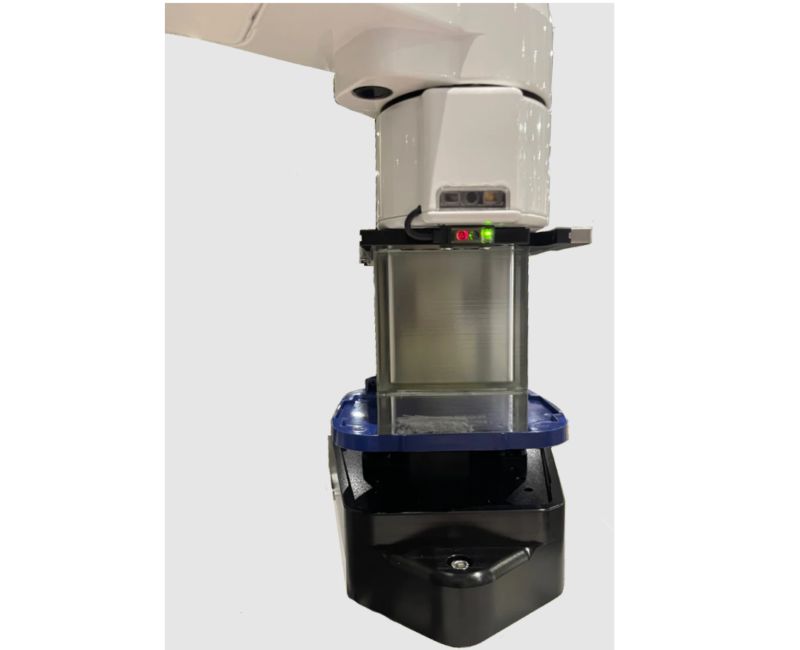

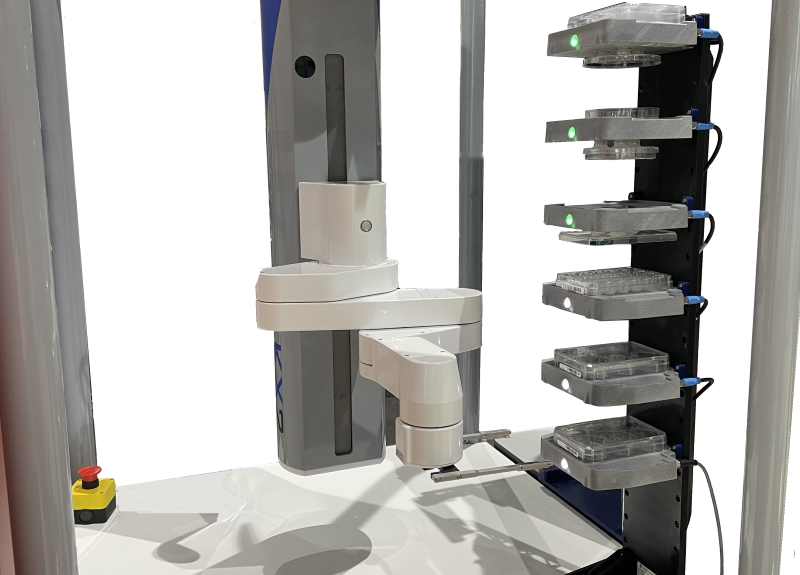

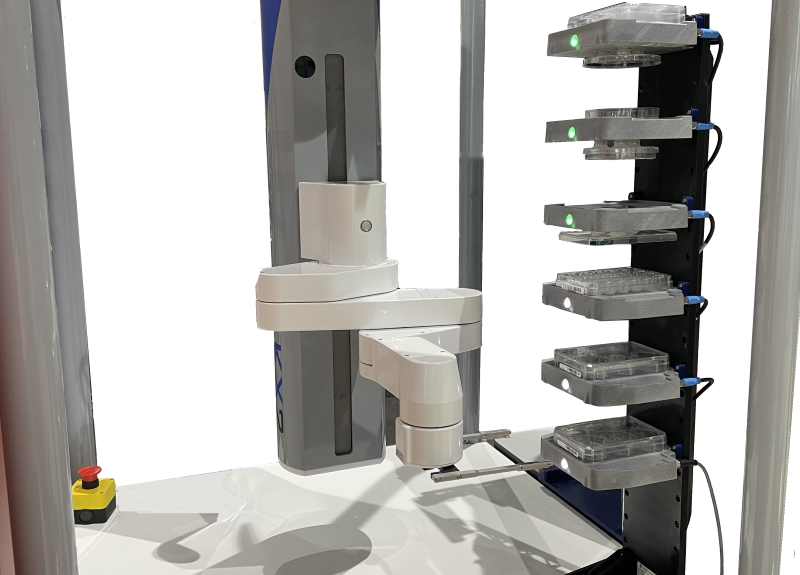

The inverted KX-2 reaches new heights to offer novel capabilities in vertical automation. With continuous rotation around the waist enabling full deck accessibility for a new generation of compact integrated solutions.

RESOURCES

- Brochures: Overlord

- Technical Notes: Laboratory Robots

Summary:

The inverted KX-2 reaches new heights to offer novel capabilities in vertical automation. With continuous rotation around the waist enabling full deck accessibility for a new generation of compact integrated solutions.

Performing rapid labware transfers with high precision motion control further increases its productivity. The inverted KX2 requires minimal structural support thanks to its industrial heritage. Its rigid design maintains its repeatability regardless of the inertia generated by its movement. The inverted mounting system is ideal for lab automation applications requiring greater reach, in hard-to-reach spaces.

Included Accessories:

- Top Grip Finger Set

- Side Grip Finger Set

- Teach Plate

Warranty:

- Includes 1 Year Manufacturer Warranty

- Additional Warranty Optional

Features

Flexible

With 360° continuous rotation of the shoulder and wrist axes and a multi-link arm, the KX2 offers extensive reach for effective use of the available space. The radial compactness of the KX2 arm, combined with a wide reach, allows easy instrument accessibility and optimal instrument placement, leading to improved instrument density, easy serviceability and increased throughput.

Easy to decontaminate

The KX2 was developed with contamination minimization in mind. The sealed design is wipe-clean with no bug traps, making it well-suited for Biosafety Level 2 applications.

High Safety

The KX2 is ideal for use on an open bench as operator safety is assured – the KX2 stops safely on human contact. The fully enclosed working mechanism ensures finger protection, making the robot fundamentally safe to use. The KX2 is fully compliant with safety standards: ISO 10218–1:2011.

Simple to set up and easy to use

KX2 features drag-to-teach technology providing easy automation of workflows. Simply move the robot arm through the pathway to the correct position and with the touch of a button the teaching is complete. In the event of power loss, the KX2 arm remains in position and the servo gripper maintains hold on the plate. On power-up, the KX2 retains taught positions, allowing immediate resumption of the workflow.

Flexible handling

The KX2 can handle a wide range of labware from different types of plates to tip racks, tube racks, petri-dishes and T-flasks, making it the robot of choice for a variety of research applications, including synthetic biology, drug discovery and biotechnology. The counter-balanced arm of the KX2 allows the handling of full deep well plates at maximum extension for optimal use of the work envelope.

Specifications

Product Name: KX2-Inverted-500

Max Payload: 500g (1.1lb)

Radial Stroke: 525 mm (20.7in)

Radial Reach: 787mm (31in) w/Side-Grip Fingers, 677mm (26.6in) to Wrist Center

Radial Compactness: 190mm (7.47in) with Gripper Facing Inward

Travel:

Shoulder: 360° Unlimited

Z: 500mm (19.69in)

Elbow: 525mm (20.7in)

Wrist: 360° Unlimited

Gripper: 26.15mm (1.03in) per finger

Speed (Max):

Shoulder: 145 deg/s

Z: 750 mm/s (29.5 in/sec)

Elbow: 467 mm/s (18.4 in/sec) avg.

Wrist: 500 deg/s

Gripper: 47 mm/s (1.85 in/sec)

Torque/Thrust:

Shoulder: 14.5Nm (128 in-lb) Peak, 7.3Nm (64 in-lb) Continuous

Z: 43.3N (9.7 lbs) Peak, 21.7N (4.9 lbs) Continuous

Elbow: 11.3Nm (100 in-lb) Peak, 5.7Nm (50 in-lb) Continuous

Wrist: 1.22Nm (10.8 in-lb) Peak, 0.61Nm (5.4 in-lb) Continuous

Gripper: 22N (5 lbs)

Encoder Resolution:

Shoulder: 8,388,608 counts/revolution

Z: 3,998 counts/mm

Elbow: 13,375 counts/mm avg.

Wrist: 16,384 counts/revolution

Gripper: 3,183 counts/mm (motion of single finger)

Repeatability:

Arm Extend: +/- 0.1mm (.004in)

Vertical: +/- 0.1mm (.004in)

Weight: 29.5 kg (65 lbs)

Height: 925mm (36.4in)

Power:

Input Power: 100-240 VAC), 1Φ, 47-63Hz, 5.6A Max @ 115VAC (2.8A Max @ 230VAC)

Output to Robot: 57VDC/5.3A/300W Max, 24VDC/3A/80W Max

Power Supply Dims: 240mm x 160mm x 90mm (9.5in x 6.3in x 3.5in)

Safety: Current & Position Error Sensing, Emergency Stop Button (Stop Cat. 1)

User I/O: 3 Digital Inputs, 2 Analog Inputs, 3 Digital Outputs

Encoders: Magnetic Absolute on robot joints, Incremental on gripper

Teaching: Drag-to-teach-point, one-touch teach button on robot, game controller (Teach Plate is included).

Gripper Options: Top-Grip (included), Side-Grip (included), Side-Grip-Portrait-Jog, Custom

PC Interface: USB 2.0